Thanks to the augmented reality solutions from 3DQR unique customer service can be designed

On behalf of valantic, we integrated our augmented reality solution to their workflow and together we took a step towards holistic customer service. With AR it is now possible to automate service instructions, to accompany technicians on every step and to exclude errors along the way.

Services, or maintenance measures in general, are in place to ensure that the functionality of equipment and resources is maintained or restored. Unfortunately, this often means a stop in production – either because the machine has broken down, requiring repair, or because the scheduled maintenance is due. Currently used remote maintenance solutions include a live communication between a trained service technician and the on-site technician of the company where the service must be performed. Especially for companies whose plants are exported or for owners of imported plants, complications can arise with this approach. For one thing, you have to factor in the time difference. If a Korean manufacturer produces with a German plant and a fault is detected in production at 10 o’clock in the morning, it is 3 o’clock in Germany at that time. Of course, in three-shift operation, these difficulties also occur in the same time zone. The next difficulty is then to find a service employee who can communicate with the Korean technician to resolve the production issue.

What remote maintenance can offer

Remote service solutions primarily offer the advantage of reducing downtime, as problems can be fixed quickly by in-house technicians. However, current remote service solutions have key disadvantages in a globalized industry. To stick with our example, the Korean technician at the plant may have to troubleshoot the problem with time differences and language barriers, making communication with the service representative in Germany more difficult and prone to errors.

Current remote service solutions that incorporate augmented reality glasses are not considered augmented reality solutions in the traditional sense. These applications involve a livestream in which a service employee from headquarters can “draw” into the technician’s field of view, thus clarifying certain instructions. Here, however, live communication between service personnel and technicians is still required.

More traditional augmented reality has the decisive advantage of being intuitively understood. Symbols, text, video or 3D objects can be viewed independent of time and language or easily translated.

Augmented Reality Maintenance with 3DQR

Until now, however, augmented reality was complicated, tedious to create and correspondingly costly. A CAD model had to be imported into the software where the AR data could be added and set up via a computer. In the next steps, the real machine had to be trained and matched with the virtual scene in a time-consuming process. However, we have created an augmented reality environment that allows you to create AR scenes quickly and easily. This means that work that used to take hours, even days, can be done in 10 minutes, and you can quickly and easily benefit from the added value that augmented reality brings.

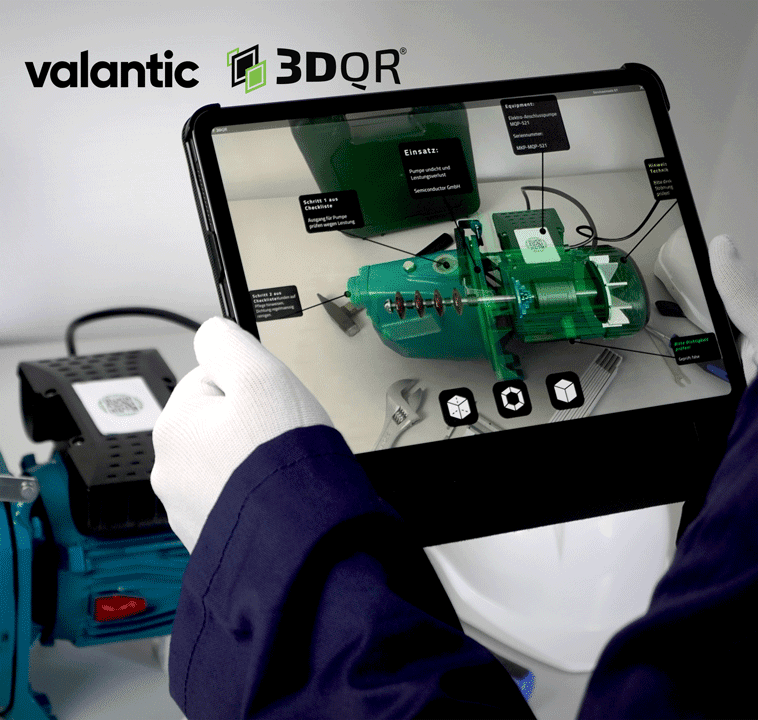

Together with valantic, we have created a service solution that combines our Augmented Reality solution and SAP Field Service Management (FSM), revolutionizing deployment planning and execution. SAP Field Service Management enables flexible deployment planning, taking into account the availability of the necessary resources, and automates all relevant information about customers and products. With the FSM tool, this information is also automatically made available to the technician and can be expanded or supplemented. A stored checklist can be worked through step by step. This avoids errors and makes the service more generally understandable.

Our embedded augmented reality solution now shows the steps directly in the overlaid model. There is no need to open a separate app and switch between two applications. Also, there is no need to buy expensive AR glasses, as 3DQR augmented reality can be accessed from smartphones and tablets.

In augmented reality, all the data that has been created in advance can now be seen, and an interactive interface makes it possible to intuitively see the function and procedure. In this way, augmented reality makes it possible for even inexperienced technicians to perform all maintenance work quickly and safely and even eliminate unplanned malfunctions quickly and flexibly.

With 3DQR and valantic, you can plan service calls flexibly and efficiently, and all employees involved can keep track of the relevant information at all times. Knowledge management supports technical staff in complicated tasks with a user interface optimized for intuition for both dispatchers and technicians. With this technology, you increase the time-to-fix rate, minimize service costs, and maintain information transparency across all involved departments and processes.

The patented 3DQR technology is based on the QR code standard and enables accurate recognition of the stored augmented reality data. The QR code is simply attached to the machine and the brand-new in-app creator enables precise adjustment of the augmented reality elements on the machine.

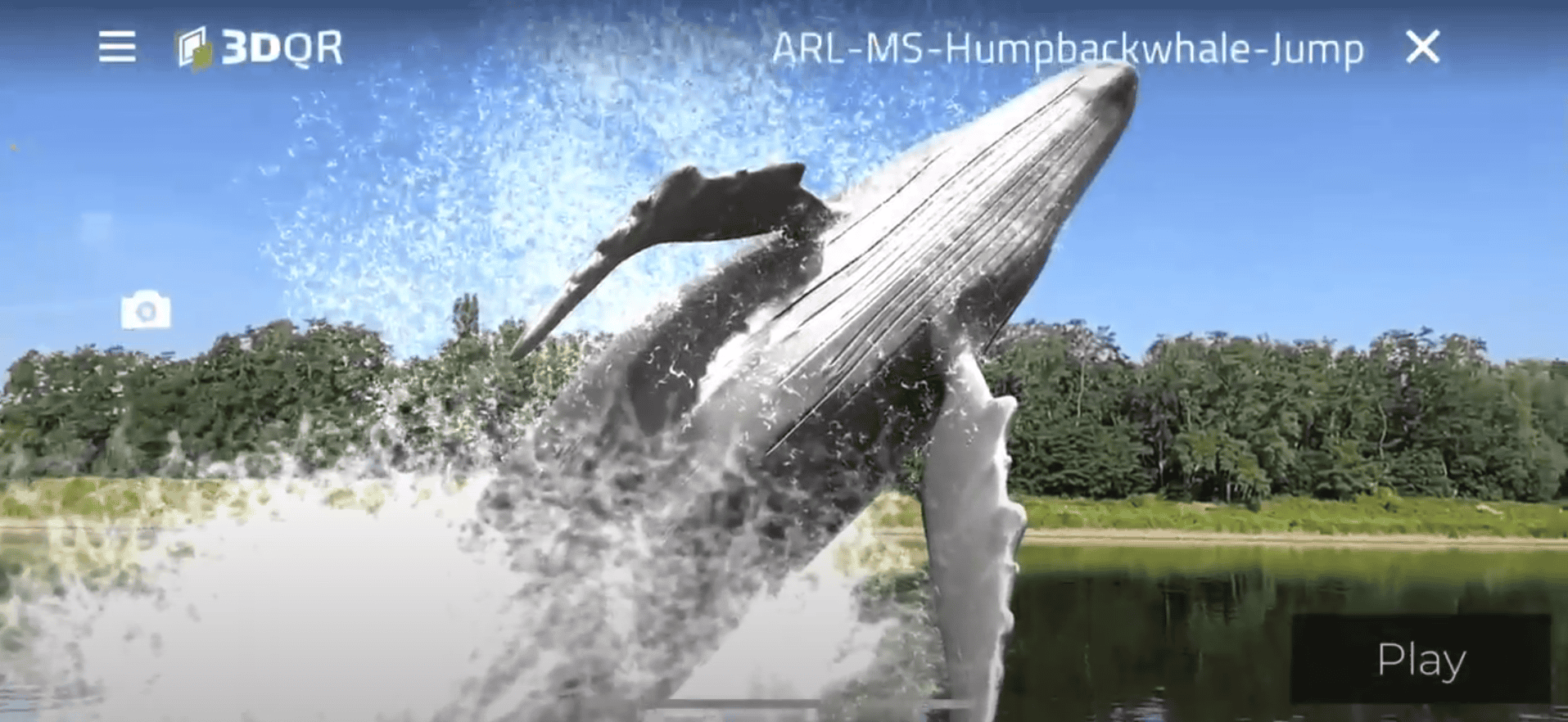

More about 3DQR

With 3DQR Studio, the 3DQR Plus app and the unique 3DQR in-app creator, as well as the QR code as an anchor in reality, we offer a way to use augmented reality to display the maintenance actions precisely on the machine. With this, we give you a tool with which you can easily and quickly create AR scenes for your service applications. With the Creator, you can easily drag and drop virtual elements, IoT data and documentation wherever you need them, add new elements or delete obsolete ones at any time and thus keep knowledge up-to-date at any time.